In the fast-evolving electrical components industry, Box Header Connectors & Ejector Header Connectors have become essential solutions for reliable, efficient, and secure board-to-board or board-to-cable connections across various applications. As a trusted connector supplier, this category addresses key challenges such as secure mating, easy installation, and long-term durability. With growing reliance on automation and modular electronics, these connectors play a pivotal role, providing dependable connectivity in demanding industrial environments while ensuring consistent performance over time. The increasing demand for high-quality electrical connections highlights the importance of selecting the right connector solutions for modern applications.

What Are Box Header Connectors & Ejector Header Connectors?

Box Header and Ejector Header Connectors are modular PCB connectors designed to provide secure electrical connections between boards or from board to cable. Box headers offer a compact, guided housing that ensures proper alignment, while ejector headers feature a locking or ejector mechanism for tool-free insertion and removal, preventing accidental disconnections and improving maintenance efficiency.

Application Scenarios for Box Header & Ejector Header Connectors

These connectors are widely used in industries requiring high reliability and frequent maintenance:

Industrial Automation: Provide fast, secure connections on control panels and modular boards, improving system uptime and simplifying wiring changes.

Communication & Networking: Ensure dependable signal connections in routers, switches, and other network devices.

Consumer Electronics: Facilitate reliable PCB-to-board or PCB-to-cable connections in computers, printers, and smart devices.

Transportation & Machinery: Maintain robust connections in vehicles and industrial equipment exposed to vibration and motion.

Advantages of Box Header & Ejector Header Connectors

Understanding their benefits helps in selecting the right solution:

Quick Installation: Ejector or locking mechanisms enable tool-free insertion, saving labor time and reducing installation errors.

Secure Connection: Locking features provide a firm grip on mating components, ensuring consistent electrical contact even under vibration or thermal cycling.

Maintenance-Friendly: Wires or modules can be easily replaced or rearranged without unscrewing, minimizing downtime.

Space-Saving & Flexible: Compact designs allow high-density PCB layouts without compromising reliability.

Durable Performance: Materials and construction ensure long-term stability in harsh industrial environments.

Next Steps

For optimal use, consult technical datasheets and installation guides from trusted manufacturers like RHT. These resources provide best practices for connector selection, mating, testing, and maintenance, helping you maximize system efficiency and reliability.

Frequently Asked Questions (FAQs)

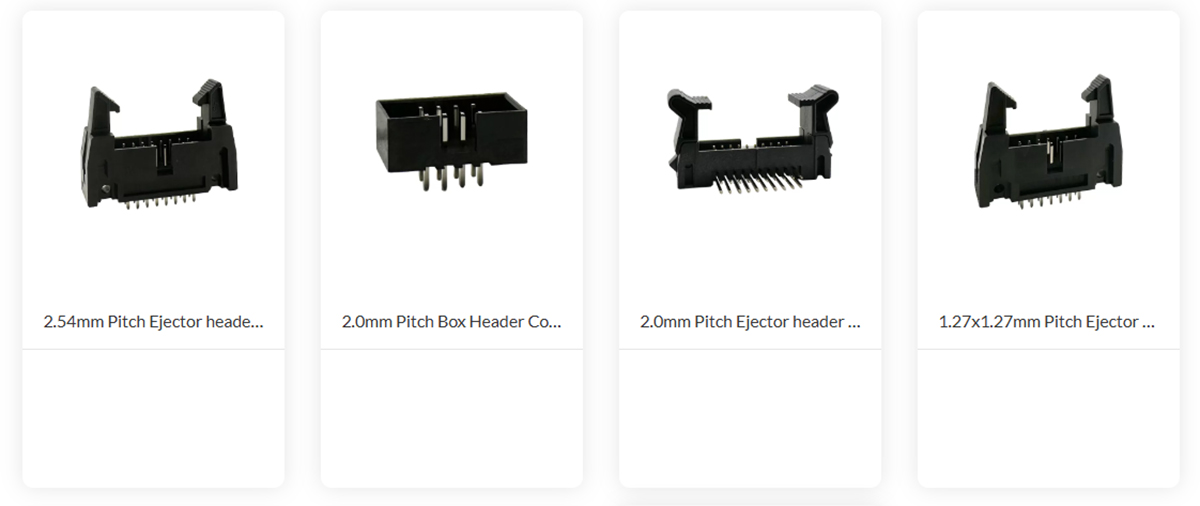

How do ejector headers differ from standard box

headers?

Ejector headers feature a locking or ejector mechanism for easy, tool-free

insertion and removal, reducing the risk of accidental disconnection. Standard

box headers rely on precise alignment and often require manual engagement.

How do I select the right connector for my project?

Consider pin count, pitch, current and voltage ratings, PCB layout space,

environmental conditions, and mating compatibility with existing modules or

cables.

Where can I find reliable Box Header & Ejector

Header Connectors?

Trusted suppliers like RHT provide a wide range of box and ejector headers with

detailed technical support and quality assurance for industrial, communication,

and consumer applications.

Investing in the right Box Header & Ejector Header Connectors ensures safe, efficient, and reliable electrical connections, whether for automation, networking, consumer electronics, or industrial machinery. High-quality connectors improve system performance, reduce maintenance costs, and future-proof your electronic designs.